Premium and On-trend

The dark indulgent colour of the glossy amber glass provides a premium look.

New growing trends such as male cosmetics and pseudo-pharmaceuticals are the perfect products for this colour of glass.

Amber glass can also provide a better finish for certain food products as there is no unsightly product residue above the fill line.

Sustainability

Because of the dark colour of amber, more recycled cullet can replace raw materials during the melting process. This means that Beatson Clark uses an average of 56% recycled material to make its Amber glass containers, compared to 36% for White Flint.

The content includes post-consumer cullet (recycled glass bottles and jars). In addition to this, any internal waste glass created through the container manufacturing process is simply recycled back into our furnace, increasing our total recycled content for amber glass to over 65%.

Flexibility and availability

Several of our general sale products are already available in amber and production runs in amber are

available from only 500k units. Unlike clear glass, production lead times are currently only 4 weeks in amber.

Therefore, both our general sale product and customer's bespoke containers can be switched to amber glass easily and quickly with Beatson Clark.

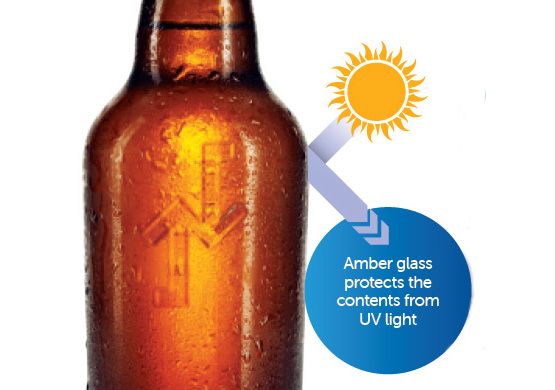

UV Protection

Beatson Clark's amber glass offers fantastic protection for your product. The dark amber colour blocks over 90% of harmful UV rays, which makes it perfect for products that can be affected by light. Products that especially benefit from this protection include beers, medicines and cosmetic products.

Glass is already an inert and safe packaging material, however this added protection increases the shelf life of a product.